OUR STORY

Established in 1989, SWR specialises in sourcing, designing and producing bespoke wire rope solutions for many of the world’s leading manufacturers across nearly all sectors and industries. SWR work closely with buyers, engineers, architects, designers and project managers to ensure the desired end result, whilst always over exceeding service level expectations. We are passionate about Wire Rope and seek to establish long-term relationships with our customers and become an integral and trusted part of their supply chain. We add additional value to our customers, by working to the highest industry tolerances using our in-house testing and material analysis equipment to ensure all our wire rope, fittings and assemblies can be fully tested and certified.

We are specialists in industries such as Marine, Outdoor Adventure & Leisure, Fall Arrest & Height Safety, Health & Fitness, Machinery, Construction, Defence, Engineering & Manufacturing, Vehicle Recovery, Fencing & Barrier Systems, Agriculture, Blind & Shade Sails, Theatre, Lighting, Pest Control, Shop Fitting and Interior Design. SWR also provide tooling and machinery to accommodate all of your requirements.

With a head office and production facility in Hemel Hempstead, UK and a network of trusted partners worldwide, we are confident we can offer exceptional lead times and expertly managed delivery schedules regardless of your demand and location. We have a strong vision to continue and accelerate our growth rate through to 2020, and beyond, to ensure that new and exciting opportunities continue to arise for our highly dedicated and determined team.

PASSIONATE ABOUT PEOPLE

We have long been a company who are extremely passionate about our people. Over the years, we have invested heavily in creating a culture where our people have a voice, and are given every opportunity possible to shine, grow and develop their careers.

SWR was founded through hard work, the owners, directors and management team are all from humble backgrounds, so collectively all understand and appreciate the importance of people. We encourage our teams to continually learn and improve in all that they do, and allow them room to reach their full potential. With the right culture, frameworks and opportunities, we believe that everyone can reach the top.

We are proud that we have achieved Investment People Accreditation Gold status, placing us in the top 10% of IP accredited employers in the industry. This recognition is a testament to our commitment to people development and creating a diverse and inclusive workplace, where all employees can thrive and succeed. We have made significant strides in recruiting, retaining, and promoting employees from underrepresented groups, and have created a supportive and inclusive environment for all of our employees. We firmly believe that diversity and inclusion are key to making better business decisions and achieving success, and we are proud to be recognized for our efforts. We will continue to strive for excellence in this area, as we believe it will bring us to be a more successful business in future.

PASSIONATE ABOUT CUSTOMERS

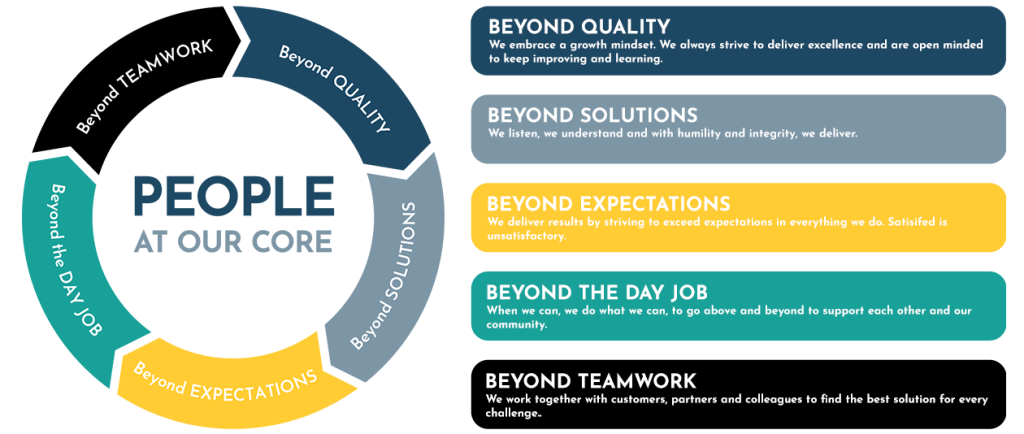

‘People at our core’ is at the centre of our values, and an integral part of everything we do here at SWR. Since the very beginning we have always organically focused on delivering a first class service to our customers. Over the years, this passion has become fully engrained in our behaviour, and is also reflected in our company mission, values and purpose.

We have recently adopted a more structured approach to consistently improve the services and products that we offer, which in turn has led us to be able to benchmark ourselves against industry leading companies, ensuring that we stay ahead of the game. We are extremely proud of our best in class NPS score of 96, which we feel supports our efforts and reassures customers that we are serious about service.

Our ‘Continuous Improvement and Innovation’ programmes have also had an impressive impact on our customers, and ensure that we don’t stand still, but instead constantly drive progression and expansion. It has become the norm at SWR for our people to constantly challenge the way we do things and generate ideas for improvement, we no longer accept a casual ‘it’s just the way we do things around here’ response. This has had an immense effect on team morale, and of course our valued customers.

PASSIONATE ABOUT COMMUNITY

Our local community is very important to us, and as such we are always looking at ways to get involved with local schools and charities. One scheme in particular involves a local school, Astley Cooper based in Hemel Hempstead, who we work with by way of an Enterprise Advisor Partnership.

We organise visits for Astley Coopers’ students to come and have a hands on experience at our Production Facility. We also support their Work Based Learning programme, which sees students gaining constructive and tangible experience working alongside our teams.

We have always been keen on encouraging and actively supporting local charities, one example of this was the introduction of our annual SWR bike ride, where our team members have taken on ever more challenging voyages each year. The most recent ride saw 11 of us complete a gruelling 124 mile journey from Hemel Hempstead to Stonehenge in support of The Hospice of St Francis, a local charity who provide life changing care for people and their nearest and dearest in our community who are living with life-limiting illnesses.