High Performance Wire Ropes

Brunton Shaw Ropes

Teufelberger Ropes

QS 810 V

114 S

Execution D6s

Execution D6

Other High Performance Ropes

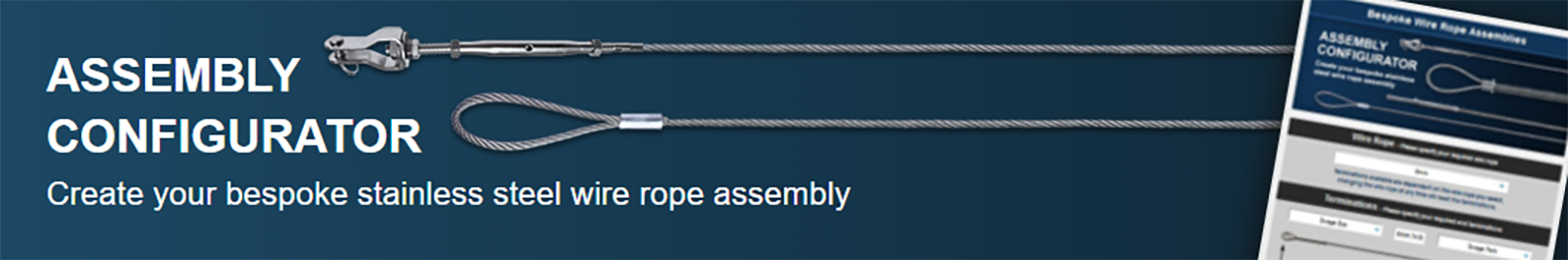

Stainless Steel Wire Ropes

Stainless Steel Wire Ropes are an important part of our core product range. We keep stock of AISI 316 Marine Grade Stainless Steel Wire Rope from 0.5mm up to 26mm in various constructions including: 1X19, 7X7, 7X19 and 6X36 wire core.

Providing high quality materials is an extremely important part of our ethos which is why our stainless steel wire ropes are produced in accordance with BSMA29 standards by one of the leading stainless steel wire rope manufacturers in the world.

Our ropes are used in demanding conditions and it is therefore vital that the tolerance and chemical composition of the material is as per the required AISI 316 requirements. Applications and markets include:structural and architectural, balustrade, yacht rigging and Stay Wire applications.

All material is fully certified and has full traceability in line with our ISO9001 procedures.

Galvanised Steel Wire Ropes

Steel Wire Rope Ltd have specialised in supplying multi stranded galvanised steel wire rope since 1989. We stock from 0.5mm up to 28mm (larger diameters available on request) in various constructions including 1X19, 7X7,6X19, 7X19, 6X36, 8X19, 8X36, 19X7 and 35X7 with both Fibre Core and Steel Cores. In addition to these conventional steel wire ropes we can offer special wire ropes from high quality manufacturers.

Most wire ropes operate in demanding conditions and must resist crushing, bending fatigue and abrasion. We recognise that it is vital that all of our wire ropes need to perform to the highest levels to maximise service life therefore increasing productivity for the end user. With our technical experience we have worked hard with our partners to ensure that all material is manufactured to the very best standards in the steel wire rope industry.

Each steel wire rope can be supplied fully assembled complete with end terminals such as a thimble eyes, swaged ends and wedge sockets as well as many other solutions. These cable assemblies are manufactured in house by our team of engineers complete to your specifications.

All material is certified and has full traceability in line with our ISO9001 procedures.